MORE ASSEMBLING OF THE TEST STAND

MORE ASSEMBLING OF THE TEST STAND

30-JUL-11

PROJECT PEAK

We've been able to do just a little in the last month on our test stand.

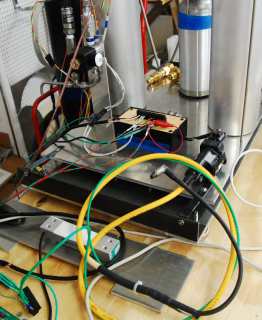

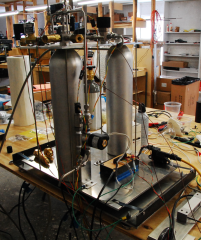

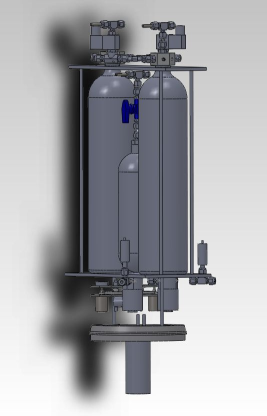

The tanks now sit on a load cell platform for monitoring propellant weights.

The platform is suspended by flat steel straps that prevent side/side and fore/aft movement but are pretty free in the vertical.

I had thought we'd put the thrust chamber right on this platform, but I'm sure the thrust would couple into the load cell measuring propellant weights, so the TC will likely sit on a separate platform (with its own load cell) with flexible lines to the CRYO valves, like we'd have on a flight platform with a gimballed TC anyway.

We've been able to do just a little in the last month on our test stand.

The tanks now sit on a load cell platform for monitoring propellant weights.

The platform is suspended by flat steel straps that prevent side/side and fore/aft movement but are pretty free in the vertical.

I had thought we'd put the thrust chamber right on this platform, but I'm sure the thrust would couple into the load cell measuring propellant weights, so the TC will likely sit on a separate platform (with its own load cell) with flexible lines to the CRYO valves, like we'd have on a flight platform with a gimballed TC anyway.

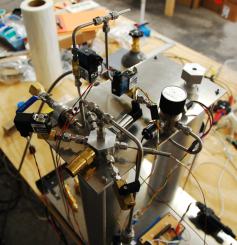

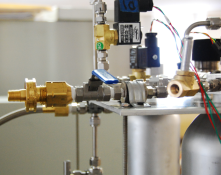

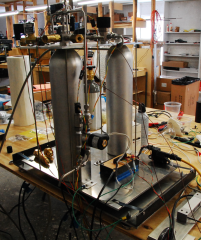

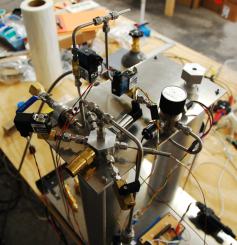

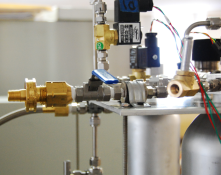

I forgot the GN2 supply check valves in our previous version so added them here when we put in the liquid side. I went vertical with them as I didn't want to extend the envelope horizontally and thought that might help isolate the systems a little better as well.

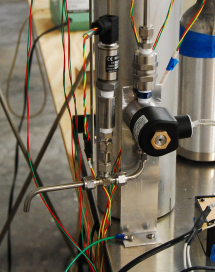

Also added a thermocouple to the tank top manifold just for grins.

You'll see it at about the 3 o'clock position on the manifold.

Nanmac makes these thermocouples up just as you want them, quick and cheap. These were about $30. Plus they throw in a bottle of hot sauce.

All the valves and sensors are connected to the computer and the program can maintain a constant GN2 pressure (+/- 5 psi band) in the LPG tank when we open the cryo valve, venting the tank through a small orifice.

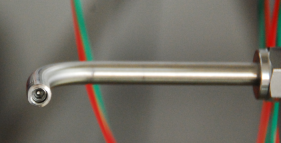

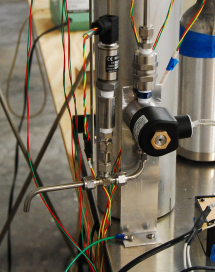

We've added the liquid side, coming down the front side of the tank to a filter and cryo valve (GEMS D2064-LN2-C301).

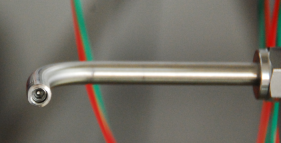

On the outlet of the CRYO valve is a pressure sensor and an outlet orifice we'll use for water testing.

It's a #10 set screw with a hole drilled through it, screwed into a bit of 1/4" tubing we threaded 10-32 (thank you Paul Breed).

The stainless set screws drill very easily.

We've added the liquid side, coming down the front side of the tank to a filter and cryo valve (GEMS D2064-LN2-C301).

On the outlet of the CRYO valve is a pressure sensor and an outlet orifice we'll use for water testing.

It's a #10 set screw with a hole drilled through it, screwed into a bit of 1/4" tubing we threaded 10-32 (thank you Paul Breed).

The stainless set screws drill very easily.

You'll see a little mini-experiment between the stainless filter and the stainless body of the cryo valve - an aluminum 1/4" pipe nipple.

I want to see what happens when LN2 hits it.

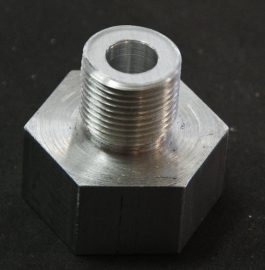

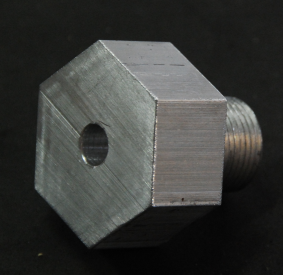

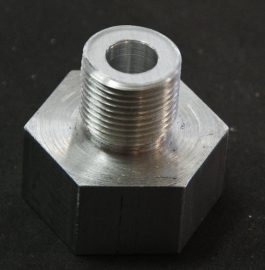

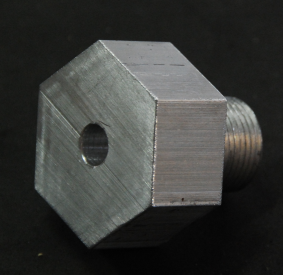

Here's an aluminum manifold blank we machined from 1 7/8" hex stock.

Just drill and tap as needed.

Seems a compact way to hang a bunch of stuff at the top of the tank.

We'll have to see how the seals work at cryo temperatures though.

Here's an aluminum manifold blank we machined from 1 7/8" hex stock.

Just drill and tap as needed.

Seems a compact way to hang a bunch of stuff at the top of the tank.

We'll have to see how the seals work at cryo temperatures though.

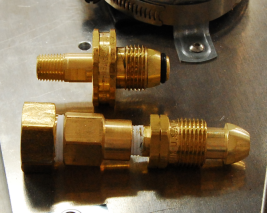

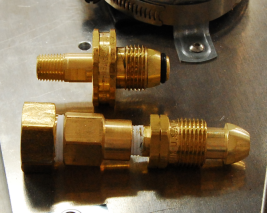

Here's our liquid propane connection.

The on board tank is filled (by weight using the platform load cell) then the isolation valve is shut and the propane fill line removed.

LPG coming in goes through a filter (under the strap) before going into the tank.

On the right are two REGO fittings.

The one with the o-ring on the nose has a 1/4" MNPT on the other end for the fill hose connection.

The bottom one is a separate fill connection we've put a garden hose fitting on for filling the tanks with water for water testing.

Here's our liquid propane connection.

The on board tank is filled (by weight using the platform load cell) then the isolation valve is shut and the propane fill line removed.

LPG coming in goes through a filter (under the strap) before going into the tank.

On the right are two REGO fittings.

The one with the o-ring on the nose has a 1/4" MNPT on the other end for the fill hose connection.

The bottom one is a separate fill connection we've put a garden hose fitting on for filling the tanks with water for water testing.

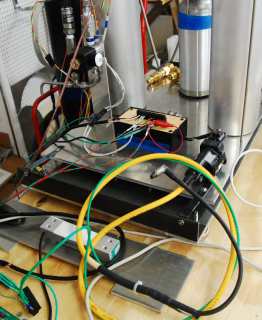

We tested the spark generator and plug.

Lots of sparks , but no effect we could see on the other electronics and computer.

Everything went fine despite repeated on/off cycles of the spark plug (with a 400 hz spark frequency).

Others have reported the LS coil is benign, and so it appears to be.

We tested the spark generator and plug.

Lots of sparks , but no effect we could see on the other electronics and computer.

Everything went fine despite repeated on/off cycles of the spark plug (with a 400 hz spark frequency).

Others have reported the LS coil is benign, and so it appears to be.

No problems from our cryo valves either, which are 120 vac actuated.

Next up ... Testing with H20, then LN2, then LO2, getting some shock diamonds and rocket noise, then maybe getting some air with the VTVL version ...we'll see what happens!

Home

We've been able to do just a little in the last month on our test stand.

The tanks now sit on a load cell platform for monitoring propellant weights.

The platform is suspended by flat steel straps that prevent side/side and fore/aft movement but are pretty free in the vertical.

I had thought we'd put the thrust chamber right on this platform, but I'm sure the thrust would couple into the load cell measuring propellant weights, so the TC will likely sit on a separate platform (with its own load cell) with flexible lines to the CRYO valves, like we'd have on a flight platform with a gimballed TC anyway.

We've been able to do just a little in the last month on our test stand.

The tanks now sit on a load cell platform for monitoring propellant weights.

The platform is suspended by flat steel straps that prevent side/side and fore/aft movement but are pretty free in the vertical.

I had thought we'd put the thrust chamber right on this platform, but I'm sure the thrust would couple into the load cell measuring propellant weights, so the TC will likely sit on a separate platform (with its own load cell) with flexible lines to the CRYO valves, like we'd have on a flight platform with a gimballed TC anyway.

We've added the liquid side, coming down the front side of the tank to a filter and cryo valve (GEMS D2064-LN2-C301).

On the outlet of the CRYO valve is a pressure sensor and an outlet orifice we'll use for water testing.

It's a #10 set screw with a hole drilled through it, screwed into a bit of 1/4" tubing we threaded 10-32 (thank you Paul Breed).

The stainless set screws drill very easily.

We've added the liquid side, coming down the front side of the tank to a filter and cryo valve (GEMS D2064-LN2-C301).

On the outlet of the CRYO valve is a pressure sensor and an outlet orifice we'll use for water testing.

It's a #10 set screw with a hole drilled through it, screwed into a bit of 1/4" tubing we threaded 10-32 (thank you Paul Breed).

The stainless set screws drill very easily.

Here's an aluminum manifold blank we machined from 1 7/8" hex stock.

Just drill and tap as needed.

Seems a compact way to hang a bunch of stuff at the top of the tank.

We'll have to see how the seals work at cryo temperatures though.

Here's an aluminum manifold blank we machined from 1 7/8" hex stock.

Just drill and tap as needed.

Seems a compact way to hang a bunch of stuff at the top of the tank.

We'll have to see how the seals work at cryo temperatures though.

Here's our liquid propane connection.

The on board tank is filled (by weight using the platform load cell) then the isolation valve is shut and the propane fill line removed.

LPG coming in goes through a filter (under the strap) before going into the tank.

On the right are two REGO fittings.

The one with the o-ring on the nose has a 1/4" MNPT on the other end for the fill hose connection.

The bottom one is a separate fill connection we've put a garden hose fitting on for filling the tanks with water for water testing.

Here's our liquid propane connection.

The on board tank is filled (by weight using the platform load cell) then the isolation valve is shut and the propane fill line removed.

LPG coming in goes through a filter (under the strap) before going into the tank.

On the right are two REGO fittings.

The one with the o-ring on the nose has a 1/4" MNPT on the other end for the fill hose connection.

The bottom one is a separate fill connection we've put a garden hose fitting on for filling the tanks with water for water testing.